When it comes to precision machining, CNC milling and CNC turning are two of the most commonly used processes. Each offers distinct advantages depending on the type of part you're manufacturing. Understanding their differences and applications can help you choose the right process for your specific needs. In this article, we’ll explore CNC milling vs CNC turning, highlighting their key features, differences, and applications.

What is CNC Milling?

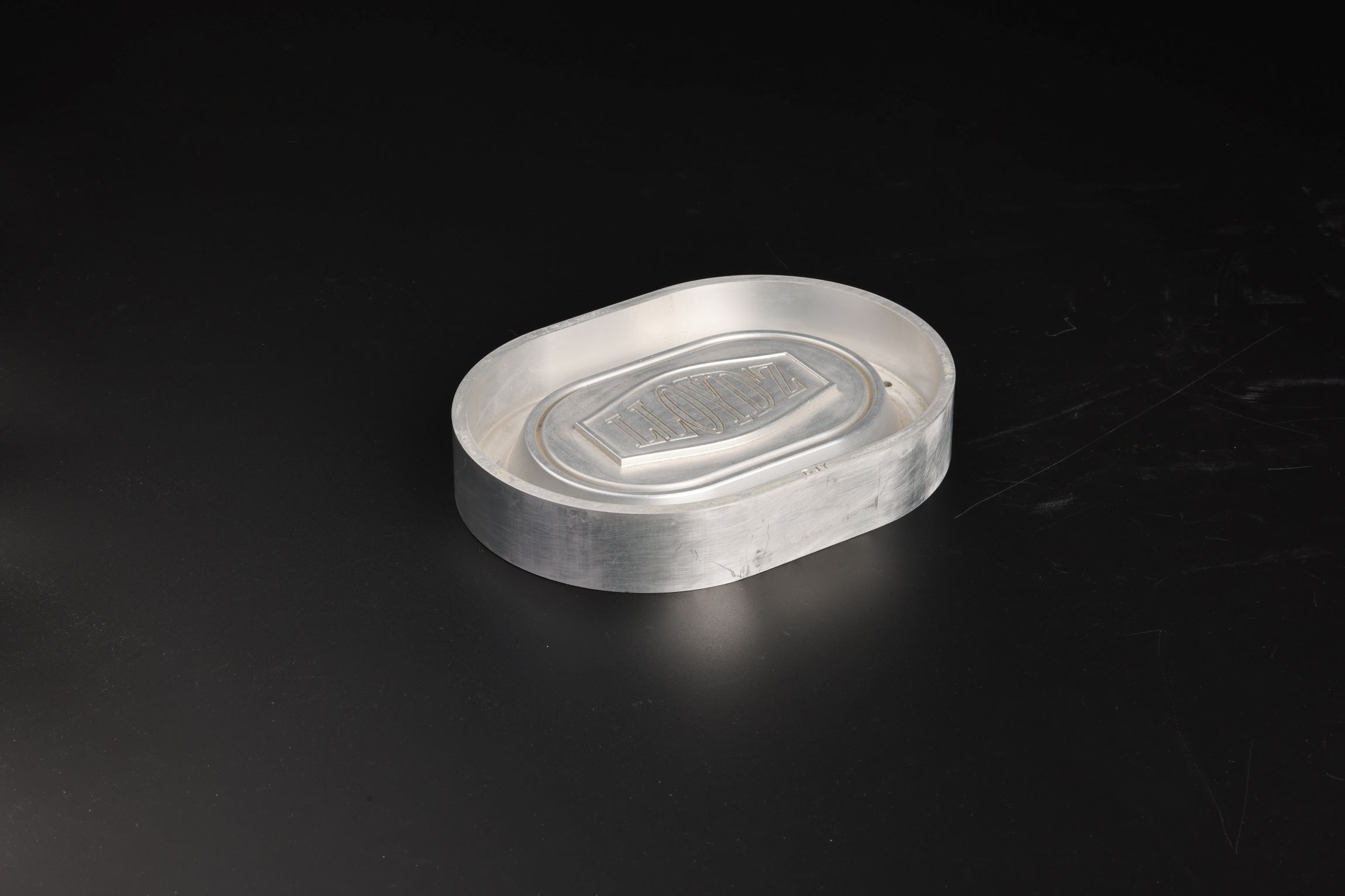

CNC milling involves rotating cutting tools that move across the workpiece to create complex shapes and detailed features. This process is ideal for parts with intricate contours, angled surfaces, and multiple dimensions. CNC milling can handle both metal and plastic materials with high precision, making it suitable for a wide range of industries such as aerospace, automotive, and medical devices.

Key advantages of CNC milling include its ability to produce complex geometries, and its flexibility with multi-axis machining, which allows for highly detailed parts with tight tolerances.

What is CNC Turning?

CNC turning is used to produce cylindrical parts by rotating the workpiece while a stationary cutting tool removes material. This process is perfect for creating symmetrical, round parts like shafts, pins, and bushings. CNC turning is ideal for high-volume production and parts requiring high concentricity and tight diameters.

Industries such as automotive, oil & gas, and industrial equipment rely on CNC turning for producing precision components efficiently and quickly.

CNC Milling vs CNC Turning: Key Differences

1. Part Shape and Complexity

- CNC milling is great for complex, non-symmetrical parts with intricate details.

- CNC turning is ideal for round, symmetrical components like shafts and rings.

2. Machining Process

- Milling uses rotating tools to move across the workpiece.

- Turning involves rotating the workpiece while the tool remains stationary.

3. Speed and Efficiency

- CNC turning is faster for producing large quantities of simple, cylindrical parts.

- CNC milling offers more versatility but requires more time and tooling for complex shapes.

Which Process is Right for Your Project?

Choosing between CNC milling and CNC turning depends on your part’s geometry, production volume, and precision requirements. If your project involves intricate designs or multi-dimensional features, CNC milling is the better choice. If you need high-speed production of symmetrical components with tight tolerances, CNC turning is the most efficient option.

At LEADMAKE, we specialize in both CNC milling and CNC turning, offering custom machining solutions for all your manufacturing needs. Our experienced team can help you determine the best process for your project, ensuring optimal quality and efficiency.

Let’s Connect!

Ready to start your project? Contact us today to discuss your CNC machining needs and find out how our services can bring your ideas to life with precision and speed.