When choosing a bending machine punch and die, there are several key factors to consider:

1. Material type and thickness: First, you need to understand the type and thickness of the metal material to be processed. Different materials (such as steel plate, aluminum plate, stainless steel, etc.) and thicknesses require different types and sizes of punches and dies.

2. Bending angle and shape: Determine the required bending angle and shape. Select the corresponding punch and die according to the required bending radius, bending angle, bending linearity and other requirements.

3. Punch and die material: Select the punch and die material suitable for the material being processed and the processing environment. Usually, materials with high wear resistance and durability such as carbide and high-speed steel are used.

4. Machine type and specifications: Consider the type, specifications and capabilities of the bending machine used. Different models and specifications of bending machines may require specific punches and dies.

5. Processing requirements and production volume: Consider the processing requirements and expected production volume. If large-scale production is required and the processing requires precision, more wear-resistant and precise punches and dies may be required.

6. Adjustability and Interchangeability: Choose adjustable and interchangeable punches and dies according to the work needs to adapt to different processing tasks and bending requirements.

7. Quality and Supplier Reputation: Choose a high-quality punch and die supplier to ensure reliable product quality and good after-sales support and service.

8. Cost and Budget: Finally, consider cost and budget constraints. When purchasing punches and dies, you need to find a balance between quality and performance and make reasonable choices based on your budget.

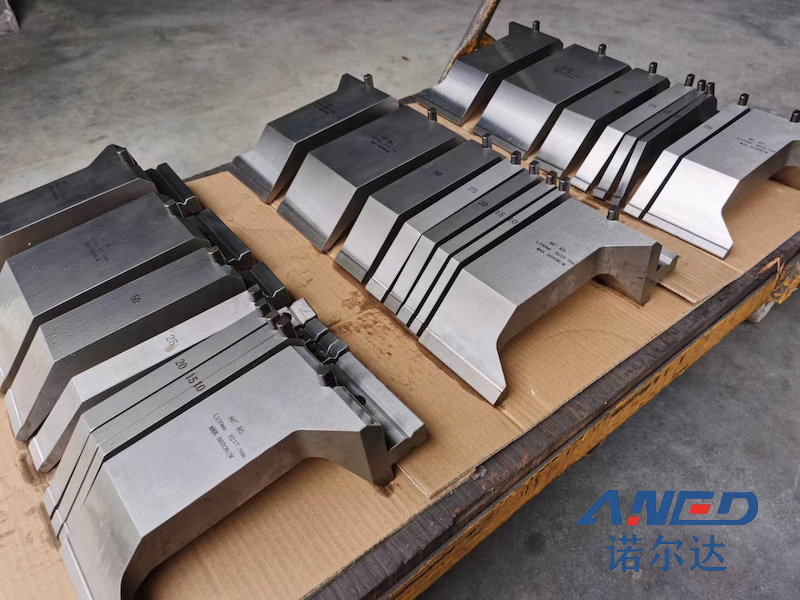

Because Maanshan Norda Tool Co., Ltd. meets all of the above conditions. We can provide high-quality bending machine tools that meet all your requirements and help you achieve accurate and consistent results.